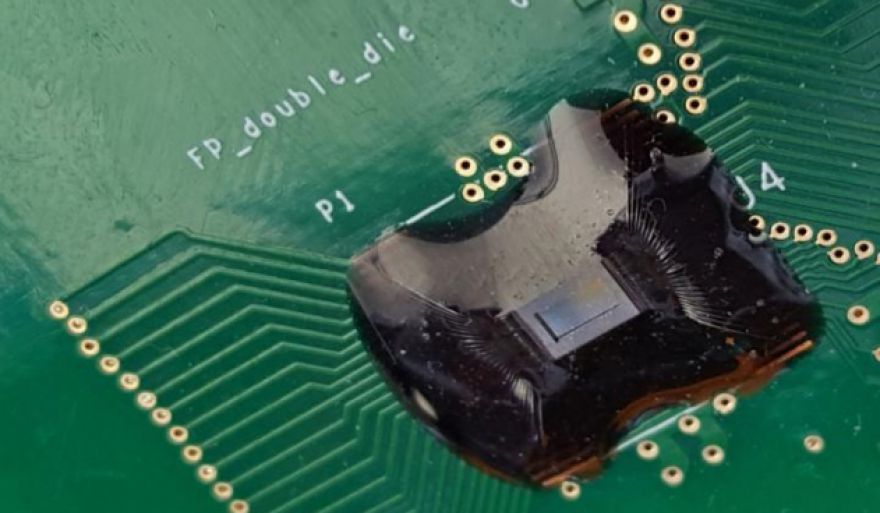

The tiny new ultrasonic sensor (image credit: Dave Horsley/University of California, Davis)

"Our ultrasonic fingerprint sensors have the ability to measure a three-dimensional, volumetric image of the finger surface and the tissues beneath the surface – making fingerprint sensors more robust and secure," says Horsley.

The sensor uses similar technology to medical ultrasound imagers. Transducers on the tiny sensor’s surface send out ultrasound pulses, which bounce off the fingerprint’s ridges and valleys before returning to the transducers. Using ultrasound means that the sensor can penetrate a thin layer of tissue near the finger’s surface, making the technology much more difficult to trick.

The chip itself is made from two wafers bonded together: a ‘complementary metal-oxide-semiconductor’ (CMOS) wafer and a microelectromechanical systems (MEMS) wafer. The CMOS wafer contains the circuitry for processing the signals, while the MEMS wafer contains the transducers.

Besides the security advantages, the researchers say that these chips will be extremely cheap to make.

“We were able to use low-cost, high-volume manufacturing processes that produce hundreds of millions of MEMS sensors for consumer electronics each year,” says Horsley.

So look out for these sensors on a smartphone near you…

By Afsaneh Khetrapal